|

|

|

Why a new approach?

Today's manufacturing industry faces big

challenges. How to deal with shorter product

lifecycles, diversified customers demands,

globalization, increased outsourcing and

collaboration? Up to now many IT systems

(such as PIM, PLM, PDM, MRP, MRPII, ...)

have been implemented each partially optimizing

engineering and production processes.

The result is an environment where information

is not sufficiently shared between departments,

collaborating companies and suppliers.

Globalization of product development and

manufacturing and shorter product lifecycles

require a better approach: Engineering

Chain Management. This innovative approach

ties product development, purchase, manufacturing

and marketing more close together by data-chaining

among all departments and suppliers.

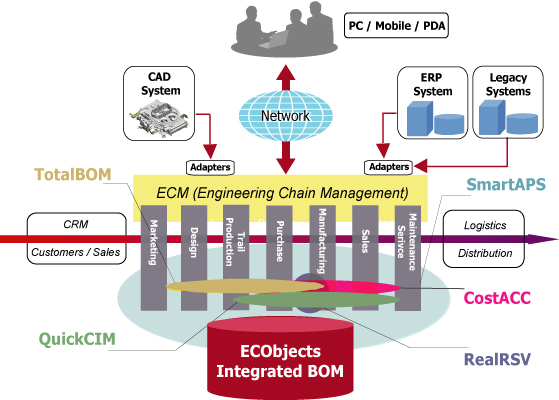

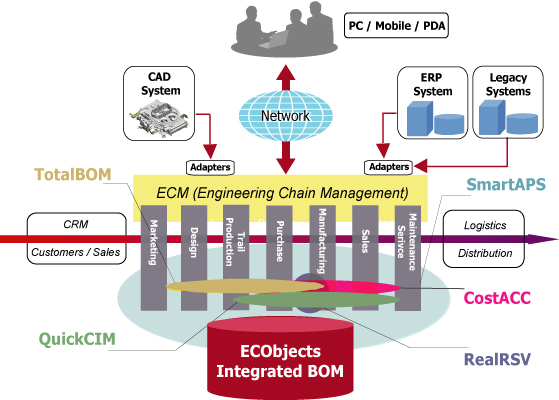

ECObjects packages

Class Technology's ECObjects packages

are originally developed to meet the needs

of the changing manufacturing environment.

ECObjects is based on the concept of ECM

and consists of six multi-lingual packages:

TotalBOM, RealRSV, SmartAPS, QuickCIM,

CostACC and CustomRCA.

|

|

ECObjects: An integrated and networked

manufacturing solution enabling information

chaining between multiple companies and

departments

ECObjects is 100% pure Java-based

with a library of more than 100 class

components. It is fully customizable through

wizards. ECObjects is build on open technologies

and runs on IBM WebSphere and Oracle application

servers. Both DB2 and Oracle databases

are supported.

|

Management System

for Product and

Engineering Information

TotalBOM is the next generation integrated

BOM offering real-time synchronization

and collaboration of processes during

the product life cycle. TotalBOM supports

functionalities for PLM, PDM, management

of the traditional bill of materials,

work flow and cost analysis. Multiple

views on the integrated BOM can be created

to satisfy information needs of the user.

With a single database, TotalBOM manages

all historic and current data. CAD data

from different systems can be easily imported

and displayed with plug-ins and a 3D-viewer.

|

Production Planning and Control

QuickCIM manages production planning and

control. All types of manufacturing are supported:

custom-made production, mass production,

MRP controlled production, and hybrid production.

When combined with TotalBOM all engineering

data can be applied in real-time improving

manufacturing operations.

|

| |

|

System Architecture Base

CustomRCA is the class library

and development environment for the ECOobjects

solution. Customization by end users is

possible through easy-to-use wizards -

program coding is not required anymore.

Applications built on CustomRCA can run

from locations through a smart client-server

and multi-layered scalable web architecture.

The system is designed for global usage

with multi-lingual support and data label

access control functions.

|

Advanced Planning and Scheduling

SmartAPS effectively utilizes

information accumulated from day-to-day

sales, shipments, and production output.

Basic data for production and sales forecasts

are derived in a short time, and can be

easily used in planning and customer documents.

|

| |

|

Real-Time Production Planning and

Resources Assigment System

RealRSV plans and assigns production

resources in real-time. A viable production

planning is made using shop floor constraints.

Based on this planning, available capacity

is committed. Supply and demand for future

inventory can be adjusted in real-time.

Cut-in scheduling for high priority orders

in case of sudden planning changes are

handled in real-time as well. Furthermore,

forward and backward scheduling can be

managed resulting in more harmonious adjustment

between received orders and production

capacity.

|

Real-Time Cost Accounting

System

CostACC makes project cost and

performance transparent and helps organizations

to better control their costs in real-time. Direct and indirect cost drivers

(ABC) are included in the integrated BOM

to manage the cost price of products.

Past, current and future inventory costs

are managed by CostACC to calculate more

accurately the actual costs of products.

|

|

home

home